SZK-30 30KW Melt blown Heater Techncial File

-

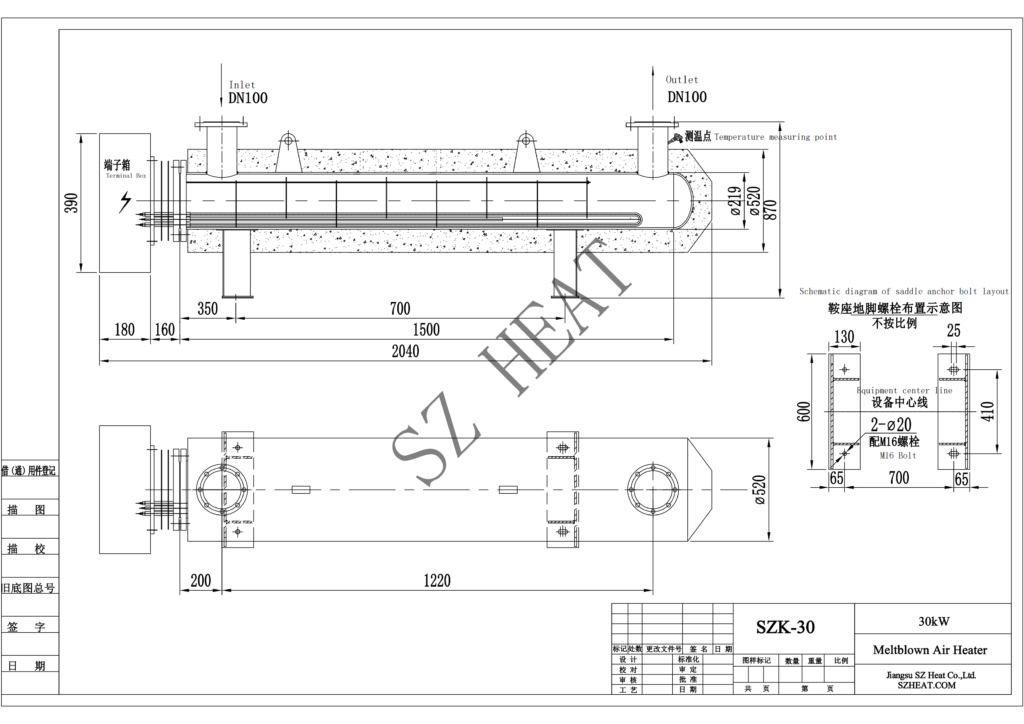

Equipment Type: SZK-30;

-

Working principle of equipment;

The air heater is a new type of environmental protection heat energy conversion equipment. Its working principle is: using electric power as energy and air as medium to heat through the heater, so as to achieve the purpose of continuously obtaining the required heat energy for the heating equipment, and meet the requirements of process temperature and high-precision temperature control set in the production process.

-

Main Technical Parameters;

3.1 Cylinder Sizes: Φ219×1500(Dia.×L mm);

3.2 Overall Sizes: 2040×520×900(L×W×H mm);

3.3 Total Powe: 30KW, 380V;

3.4 Design Temperature: 350℃;

3.5 Working Temperature: 300℃ (Adjustable);

3.6 Air Inlet & Outlet: DN100, 1.0MPa;

3,7 Heating Medium: Air, 0.5MPa;

3.8 Weight: 550KG;

-

Configuration Of Main Raw Materials;

4.1 Heating Cylinder: Inner material is S.S.304;

4.2 Flange: S.S.304, DN100, 1.0MPa;

4.3 The Heater: It is composed of several 304 stainless steel electric heating tubes;

4.3.1 Wire Resistance: Cr20Ni80;

4.3.2 Sheath Tube: Seamless tubes Dia 10mm, S.S.304;

4.3.2 Hi-pot test: 1800V/min

4.4 Gasket: metal wound gasket;

4.5 Terminal Box: The upper end of the heating tank is provided with a terminal box with a protective shell. The terminals of all the heating tubes are arranged at the terminal box, and the terminals of the heating tubes are led out through a copper plate.

4.6 Temperature detection point setting:

4.6.1 Outlet temperature measuring point: set at the outlet of heater, using armored thermocouple, index PT100;

4.6.2 Cylinder protection measuring point: it is set in the center of the heater, with armored thermocouple and PT100 index;

4.7 Heat preservation layer: the heat preservation layer is installed outside the heater cylinder, and the heat preservation material is high-density aluminum silicate fiber, with the thickness ≧150 mm;

4.8 Welding: the type and size of welded joint shall comply with HG20583-1998

-

Control System;

5.1 Temperature Control: The temperature of the air outlet is detected by the air outlet temperature sensor and transmitted to the control system. Once the outlet temperature is close to the set value, the temperature controller outputs a signal to control the thyristor power regulator, so that the outlet temperature of the heater is always constant at the set temperature value, and the controllable accuracy is ± 1 ℃. The temperature curve is smooth and the temperature control precision is high.

5.2 Tube overheating protection: the heating inner tank center is equipped with a temperature measuring probe to transmit the detection temperature signal to the temperature control module. Once the temperature exceeds the set value and the power supply is automatically cut off, the heating will stop heating, and the alarm indication will be sent out to remind the operator to note that adopting this protection method can effectively ensure that the heater will not be damaged due to dry burning caused by air circulation or other factors, It can effectively extend the service life of electric heater.

5.3 Electrical components

5.3.1 Temperature Controller

5.3.2 Air Switch

5.3.3 Contactor

5.3.4 Indicator Light

5.3.5 Buttons

5.3.6 Solid State Relay

5.3.7 Temperature Sensor

5.3.8 Thermal Relay

5.3.9 Explosion Proof Terminal Block

-

Main Parts Of Equipment;

6.1 Flange Heater

6.2 Heating Cylinder

6.3 Temperature Sensor

-

Environmental Requirements;

7.1 Indoor places with ventilation or ventilation;

7.2 The ambient temperature is in the range of – 20 ~ 50 ℃;

7.3 There is no conductive dust, corrosive gas that can seriously damage metal and insulation around;

7.4 Not exposed to direct sunlight;

7.5 The installation ground shall be flat and firm without obvious vibration.

-

Manufacturing Acceptance Standards;

8.1 Acceptance according to the technical terms of the contract;

8.2 According to the design drawings and design changes confirmed by both parties.

-

Scope Of Supply;

9.1 Air Heater 30KW 1 set

9.2 Control Cabinet 1 set

-

Equipment Assessment Index;

10.1 Beautiful appearance, no defects, and enough steel, no matter cold or hot deformation;

10.2 The sealing parts are all made of high temperature resistant metal wound gasket, with good sealing performance and no leakage at all;

10.3 System sealing test: 1.0MPa was used for air tightness test;

10.4 Tank surface temperature: ≤ 50 ℃ (relative to ambient temperature);

10.5 After derusting, the surface of carbon steel is coated with two layers of antirust paint and two layers of finish paint, with smooth appearance and uniform color;

10.6 After installation and debugging, the equipment has been running for 72 hours without any fault.

Leave A Comment