Immersion Heaters: Your Ultimate Solution for Efficient Heating

In the world of industrial heating solutions, immersion heaters play a pivotal role in various sectors. This comprehensive guide explores the diverse facets of immersion heaters and highlights why choosing SZ Heat as your trusted supplier heaters play a pivotal role in various sectors.

1. Introduction

Welcome to the world of immersion heaters, where efficient heating solutions meet unwavering commitment to quality. In this in-depth guide, we’ll navigate the landscape of immersion heaters, offering insights into their diverse applications and the advantages of partnering with SZ Heat.heaters, where efficient heating solutions meet unwavering commitment to quality.

2. Understanding Immersion Heaters

Immersion heaters are versatile heating elements engineered to efficiently heat a wide range of substances, making them indispensable in numerous industries. Let’s delve into the fundamental workings of these heating marvels and their vital role in your processes.

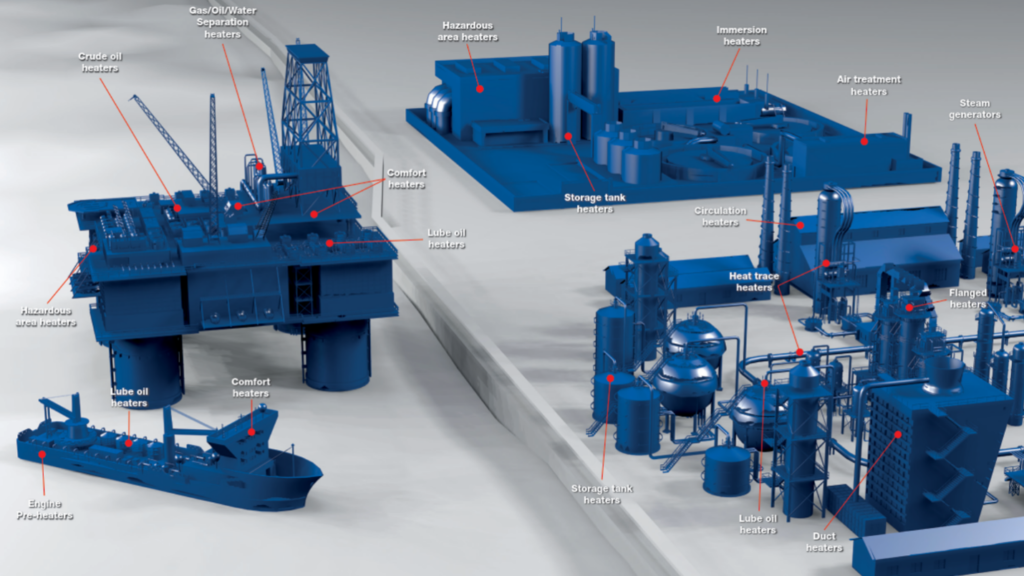

3. Applications of Immersion Heaters

For over 20 years, we have been producing high quality and efficient electric heaters for use in industrial settings. We already work with for the following industries:

Oil & Gas

Government

Water

Pharmaceutical

Military

HVAC

Process

Waste & Biofuels

TECHNICAL

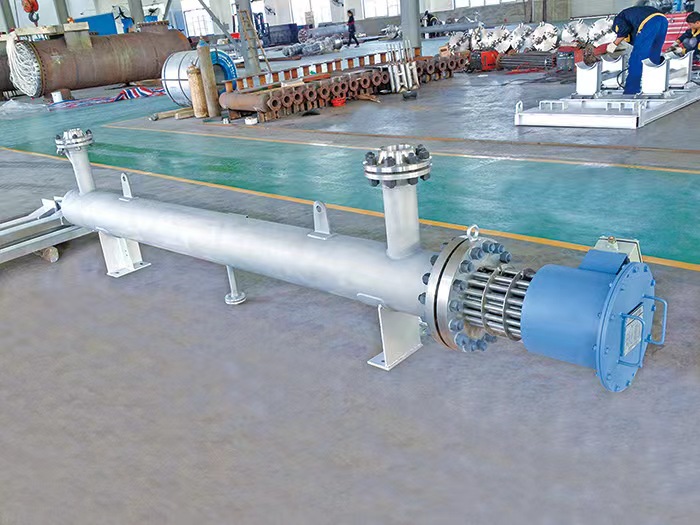

HEATING ELEMENT

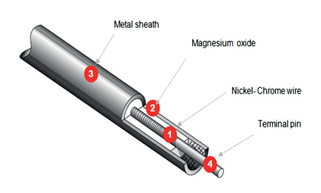

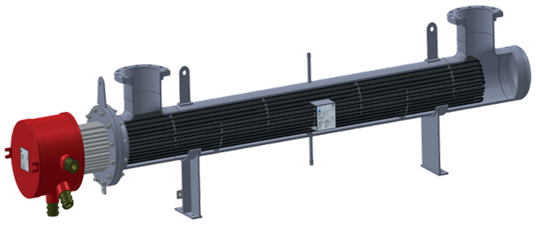

We offer Tubular sheathed Heating elements having high-quality Ni-Chrome resistance wire within electric insulation made of compact magnesium oxide covered by a metal sheath made of Varied materials (carbon Steel, SS 304/316/321/321L, Incoloy 800, Incoloy 825, Hastelloy, Inconel etc.) to suit the process condition. Heating elements can be supplied in different diameters (Ø 6.25 — 16 mm) and length.

The heating elements would pass through the tube sheet, be seal welded, and terminated in a stainless steel enclosure. The heaters are designed in accordance with (IEC 60079-0: 2011, IEC 60079 – 1: 2007, and IEX 60079-31:2008). Explosion proof of Exd II BT5.

The terminal box will be rated to IP65 (SS 304 Full Weld to the flange), be fitted with plugged, drilled conduit entries for cable entry. The heater bundle is designed to suit an ambient temperature of 25ºC. However, the client should ensure that the terminal box is not subject to direct sunlight at ambient temperatures above 30ºC. An optional sunshade or canopy is required to reduce terminal box heating through solar gain (by others). The heater would have an over temperature RTD. The heater would have one RTD’s strapped to the elements to monitor element temperature.

Element over temperature protection is provided but this should not be the sole means to trip the heater in the event of a low flow situation occurring (PID Process controller is recommended to control the electrical heater during its normal operation). The elements would be supported in a segmental stainless-steel baffled assembly 200 mm pitch which would be tack welded to tie rods. The terminal box would be designed to accommodate up to 1 x 3 core 50mm² cables. These are maximum acceptable sizes only, given for information. Actual cable requirements will vary depending on individual circumstances and should be verified by the customer.

| kW Rating: | Up to 5000 kW |

| Element Metallurgy: | Carbon Steel, SS304/316, Incoloy/Inconel |

| Element Diameter (mm): | 12 mm |

| Watt Density: | up to 3 Watt/cm2 |

| Flange Class: | 150, 300 or more as required |

| Flange Metallurgy: | Carbon Steel, SS304/316/321 or as per process requirement |

| Terminal Box Metallurgy: | Carbon Steel, Cast Aluminum, SS |

| Area of application: | Available for both Hazardous & safe area application |

| No. & size of entries: | 2 & more |

| Temperature Control: | Thermostat/ RTD/ Thermocouple |

| Voltage: | 220/230, 380/400 VAC Single & 3 Phases |

| Certificate: | ATEX – IECeX (CE) |

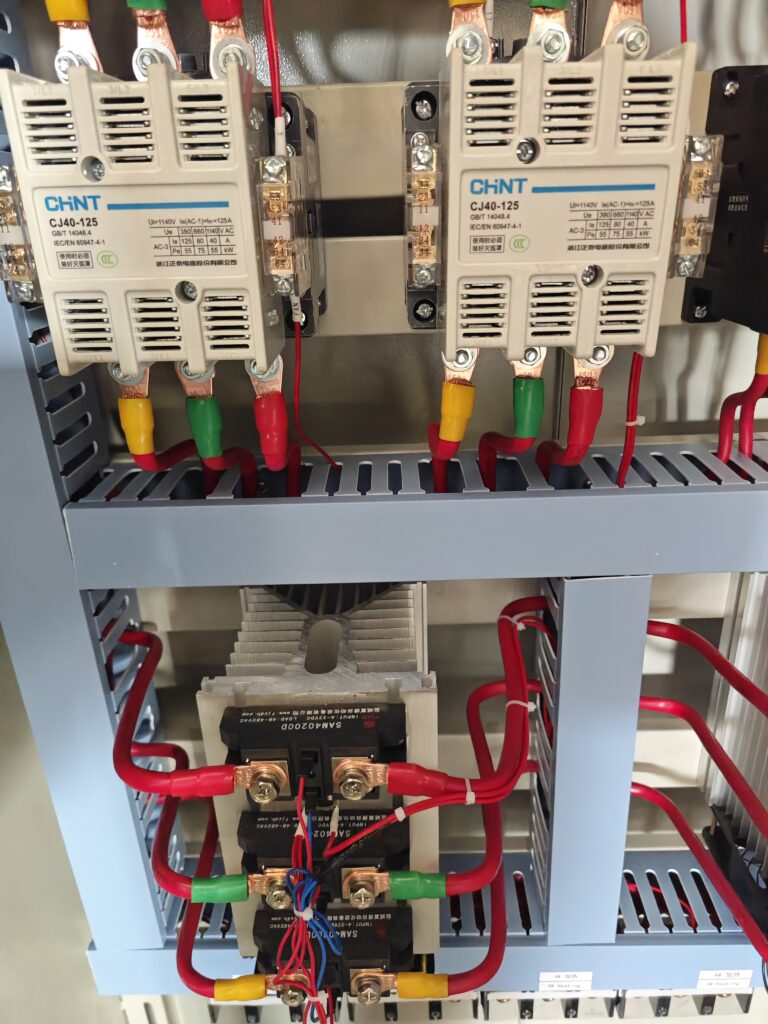

CONTROL PANEL

- ON/OFF CONTROL

This type of control relies upon mechanical contactors and switches the load on or off from a demand signal received from the sensors mounted on the heater. It should be noted that this type of control system is best suited to static applications such as heaters for tanks/vessels as the degree of accuracy which can be applied is limited by the reaction time of the contactor and the number of stages available. Slightly more sophisticated systems incorporate multiple stages to allow a degree of flexibility.

- THYRISTOR CONTROL

This type of control is the most common system used in flowing systems as the infinitely variable thyristor (SSR) switching device can very quickly adjust the heater power to match exactly the demand signal sensing the process fluid or gas temperature.

- BASIC COMPONENTS FOR A HEATER CONTROL PANEL

- Enclosure typically IP55mild steel for indoor mounting

- Main isolator

- On/off switch

- Warning lamps

- Low voltage control circuit

- Over temp controller (s)

- Process temperature controller

- Circuit protection fuses or MCCB

- Power switching device (s) either contactor or thyristor

- Trip device

HEATER CONTROL

All stages of the heater(s) will be energized simultaneously from 0-100%, in response to a 4-20 mA control signal supplied from the client’s DCS. The thyristor stack would comprise of an inverse – parallel connected pair of thyristors in two of the three phases. The thyristors would be fired at the zero-voltage point by a single cycle type thyristor driver; the nominal harmonics generation across all values would not exceed 5% THDV.

Protection of the thyristor would be by means of rapid acting semiconductor protection fuses and voltage transient suppression circuits. The temperature indicating controller would be a three term P.I.D, device with a digital display offering the following facilities.

- Auto/Manual Control

- Dual Digital display showing setpoint and process variable.

- Auto tune

The thyristors would have minimum peak inverse voltage rating of 2.5 times the maximum RMS line voltage and could work continuously at full current in the maximum ambience of 30°C. The thyristor driver circuits would not be sensitive to, nor produce radio frequency interference. Suitable protection would be incorporated into the equipment to ensure that faults in the thyristor power or trigger circuits would not cause damage to the control equipment. All secondary control wiring would be carried out using black, flame retardant, low smoke, zero halogen cable to IEC 331/332 with a minimum C.S.A. of 1.5mm. All internal components would be identified and cross-referenced to the panel schematic drawings. The thyristor power controllers would be fan cooled if required.

Trip Conditions

Unless otherwise indicated the following faults would cause the main contactor to de-energize and thereby shut off the power to the heater stage.

- Element Overtemperature

- Heater Overtemperature

- Panel Overtemperature

- Earth Leakage

All trip signals would be latched within the control system and would be manually reset before the heater stage could be restarted.

Indications

The following conditions would be monitored locally.

- Power On

- Heater On

- Heater Off

- Elements Overtemperature

- Heater Overtemperature

- Panel Overtemperature

- Earth Leakage

Control

The following local control functions would be available:

- Heater On

- Heater Off

- Trip Reset

- Earth Leakage Reset

GENERAL

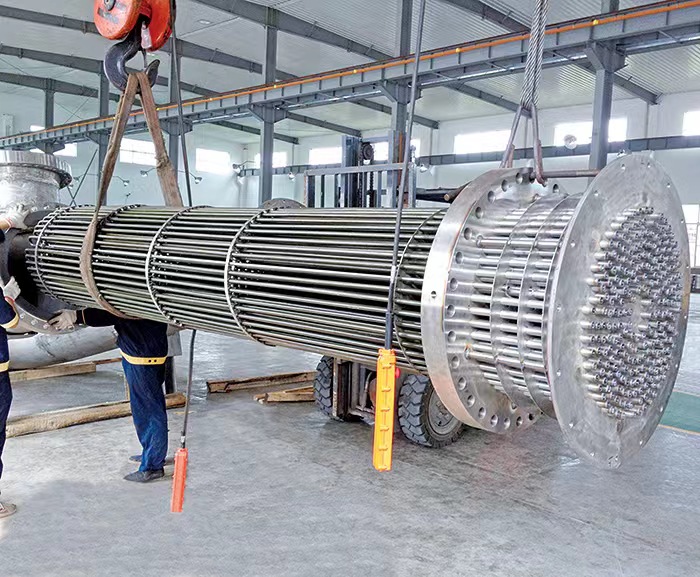

SZHEAT was founded in 1998 and we are committed to manufacturing and marketing heating elements. As the leader in the heating element industry in China, our company has now become one of the best suppliers of famous big companies such as SRC, Duratex, SiccaDania, PT. Pacific Process Engineering,Kinectrics and Weberand. Etc.

With a stable domestic market in China, SZHEAT has started exporting and already established an extensive customer network in the USA, Europe, Southeast Asia, and Russia. Our annual production capacity is up to five million pieces. These figures are increasing with our new production facility. SZHEAT specializes in the production of sheathed electrical heating elements and in a wide spectrum of electrical heating solutions suitable to meet most of the applications in different industrial sectors. All our products are manufactured under the most stringent quality tests according to the main China & International Standards.

Services for SZ HEAT B2B Clients

At SZ HEAT, we prioritize providing tailored solutions to meet your specific business needs in the electric immersion heaters, industrial immersion heaters, and tubular heater elements industry. Our professional services include:

Customizable Technical Design

- Leverage our expertise to create electric immersion heaters designed to your precise specifications.

- Discuss your requirements, and we’ll craft a solution that aligns with your business objectives.

Competitive Prices

- Enjoy competitive pricing without compromising on the quality of our products.

- We understand the balance between cost-effectiveness and maintaining the high standards your clients expect.

Quality Assurance

- Our commitment to top-quality products is unwavering. All our electric immersion heaters undergo rigorous quality inspections and certifications.

- Rest assured that your clients will receive reliable and durable heating solutions.

Certification Transparency

- Avoid the pitfalls of certificate fraud. We provide transparent and verifiable certification for all our products.

- Trust in the authenticity of our certifications to meet industry standards and regulations.

Fast Delivery

- Time is crucial in your industry. Benefit from our efficient supply chain and logistics to ensure timely delivery of your orders.

- Streamlined processes to minimize lead times and meet your project deadlines.

Competitive Prices

- As a B2B wholesaler with a global footprint, we specialize in exporting to various countries.

- Navigate international trade seamlessly with our experience in catering to diverse markets.

Responsive Communication

- We value clear and efficient communication. Our dedicated team ensures prompt and effective responses to your inquiries.

- Experience a hassle-free collaboration with a supplier who understands the importance of streamlined communication.

Logistics Management

- Overcome the challenges of logistics with our comprehensive management services.

- Timely deliveries, organized shipping, and meticulous tracking to ensure your products reach their destination without delays.

Partner with SZ HEAT for a reliable B2B relationship where your business objectives are our top priority. If you have specific requirements or would like to discuss potential collaborations, feel free to reach out. We’re here to elevate your business to new heights.