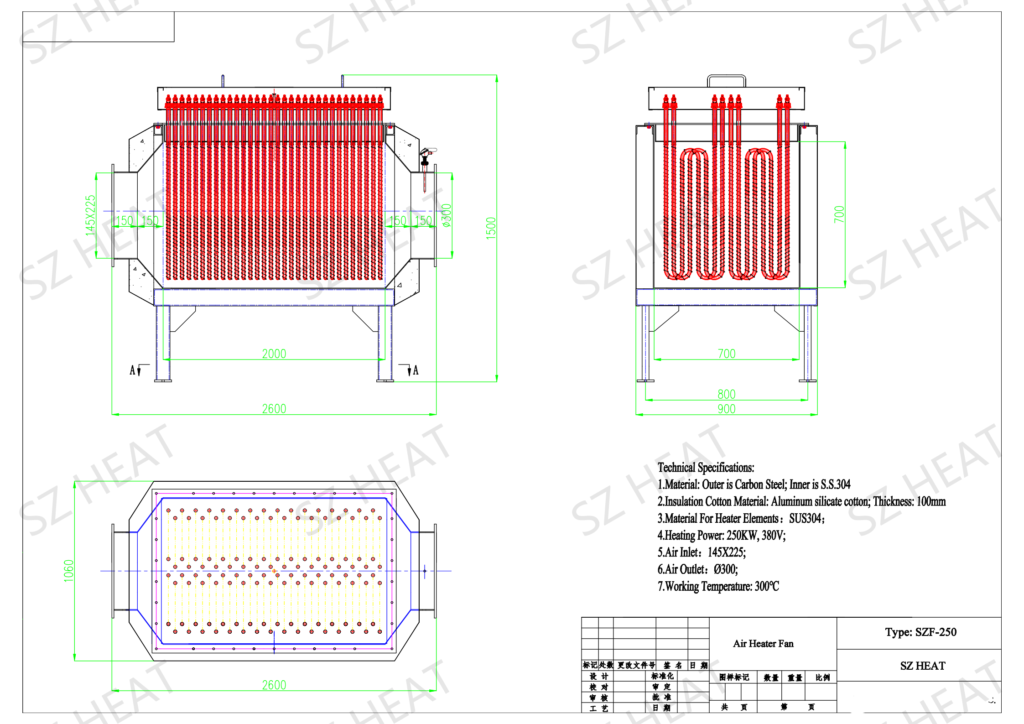

I Model: SZF-250

II Equipment Feature

This kind of Thermal Oil Heater is a kind of new-typed heating equipment with heat energy conversion. It takes the electricity as power, air as the medium. The air is forced to be blown into the heater for heating through the fan, to meet the purpose of continuously obtaining the required heat energy for the equipment, and meet the requirements of the temperature setting in the production process and the high-precision temperature control.

III Main Technical Parameters

- Outer Dimensions: 2600×900×1500(L×W×H mm);

- Power: 250kW,380V;

- Design Temperature: 400℃;

- Working Temperature: 300℃(Adjustable);

- Air Inlet: 145*225;

- Air OutletΦ300;

- Heating Medium: Air;

- Weight: 600KG

IV Main materials configuration

- Mechanical part

- Heating Body: Inner is S.S.304, Outer is Carbon Steel

- Flange: S.S.304

- Electric heating pipe: shell is 1Cr18Ni9Ti, Φ12seamless tube with fins

- Heating wire: Cr20Ni80

- Pressure resistance: 1800V/min

- Terminal Box: The upper of the heating tank body is provided with a terminal box. The terminal box is equipped with a protective shell, and the terminals of all heating elements are arranged at the terminal box, and the terminals of heating elements are led out through copper plates.

- Temperature detection point setting:

1 ·Outlet temperature detection point:It is set at the outlet of heater and adopts armored platinum resistance. Graduation PT100;

2 ·Cylinder protection detection point:It is seted at center of the heater and adopts the thermocouple. Graduation K;

- Thermal insulation layer: The heat preservationlayer is added outside the heater body, the thickness is ≥100mm;

- Welding: the type and size of welded joint shall be in accordance with HG20583-1998.

Electrical components:

- Temperature controller(PID) : Omron

- Air switch: Chint

- Contactor: Chint

- Indicator light: Chint

- Button: Chint

- 6. SSR : from Wujie

- 7. Temperature detection: from Shanghai Tianhong

- 8. Overtemperature relay: Chint

- 9. Terminal strip: Fenghuang

V Environmental requirement

- An indoor space with ventilation or fresh air.

- Ambient temperature is between -20℃ and 50℃.

- No electric conductive dust, and no corrosive gas which can severely damage metal and insulation in the around.

- Without direct sunlight.

- Smooth and strong of the mounting floor without obvious shake.

VI Equipment manufacture and acceptance standard

- Acceptance according to the technical terms of the contract;

- Check and accept according to the technical drawings and design changes which confirmed by both parties.

VII Scope of supply

- Air Heater Fan: 250KW, 1 set;

- Control System: 1 set.

IX Equipment evaluation indexes

- Appearance is free of defects and there is enough rigidity, doesn’t deformation whatever cold state or thermal state

- Sealing parts all use high-temperature metal winding pads, sealed performance is good without leaking.

- The Sealing test, the system does the air-tight test at a pressure of 1.0Mpa.

- The Surface temperature of the furnace is ≦35℃ ( relative to ambient temperature ).

- The Carbon steel surface is painted two antirust paint and two topcoats after rusting removal. And the appearance is smooth, bright and clean, the colour and lustre are consistent.

- After the installation and commissioning of the equipment, there is no fault after 72 hours of operation.

If need more technical information, please contact us freely.

Leave A Comment