I Equipment feature

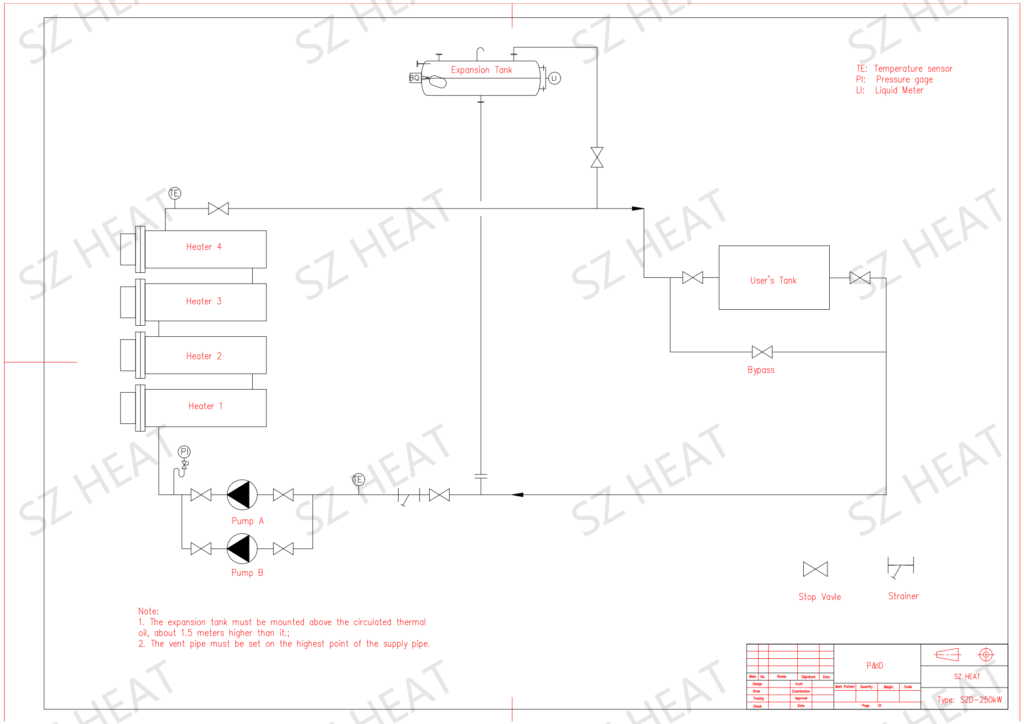

This kind of Thermal Oil Heater is a kind of new-typed heating equipment with heat energy conversion. It takes the electricity as power, changes it into the heat energy through the electrical organs, takes the organic carrier ( heat conduction oil ) as a medium, and continues to heat through the compulsive circulation of the heat conduction oil driven by the high-temperature oil pump, so as to meet the heating requirements of users. In addition, it could also satisfy the requirements of set temperature and temperature controlling accuracy.

II Equipment characteristic

- This equipment uses electric energy as a heat source, clean, no smoke, no environmental pollution, non-corrosive to the device, no effect on workers’ health.

- High thermal efficiency, can reach 95%, under the working conditions heating-up fast, and temperature uniformity.

- Low pressure. At the low working pressure, it can get a higher working temperature, and the pressure is only seven one-tenth of the saturated vapor pressure, completely without a run, emit, drop, leakage phenomena, safety and reliable, doesn’t need a man on duty for 24-hour.

- A wide range of temperature regulation, high precision of temperature control, having complete operating control, and safety monitoring devices, the precision of oil furnace temperature is about 1 centigrade degree, so it is easy to operate.

- This equipment structure compact covers a small area, easy to maintenance. It can be horizontally mounted nearby the hot equipment and doesn’t need a special boiler room.

- Save the water treatment equipment and a mass of boiler water.

III Performance index

- Heating power:250kw

- Power supply: 380V 50Hz

- Oil pump power: 11kw ( flow: 45m3/h,head: 40m )

- Heating medium: heat transfer oil

- Temperature control precision: ±1℃

- Design temperature: 320℃

- Working temperature:300℃ (adjustable)

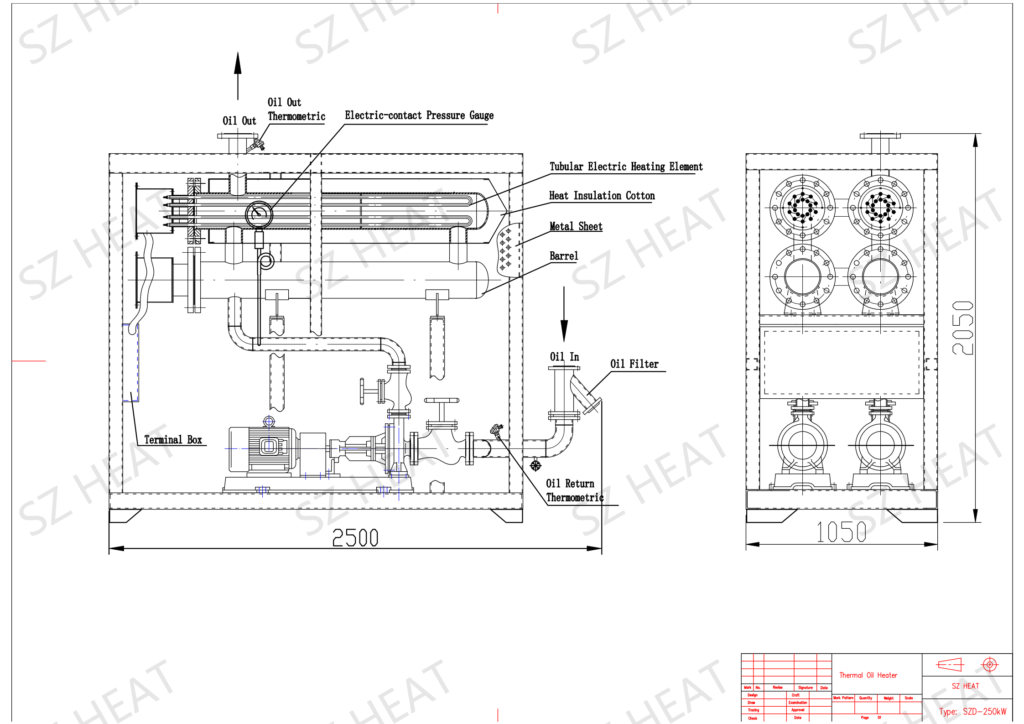

- Outside dimention: 2500 x1050x 2050 ( L x W x H mm )

- Weight: 800kg

IV Structure and control

- furnace body: It is welded by 4piecs seamless tube of Φ219, and the main part is welded by structural steel with sufficient bearing ability. Heating barrel external insulation uses the high-quality alumina silicate fibre, high temperature cut-off valve is connected between the barrel and pump.

- Electric heater: It is made up of 1 unit flange heater, and every flange heater is welded by a stainless steel heating pipe with a certain number of spare. The shell material of the heating pipe is 1Cr18Ni9Ti seamless stainless steel pipe, the heating wire is the imported high resistance Cr20Ni80, the fillers are all high-level magnesium oxide powder, temperature resistance, pressure resistance and extending the service life.

- The hot oil pump is a high-temperature centrifugal pump produced by Wuan Industrial Pump Co., Ltd. with long sustainable operation time.

- Temperature control: Signals transmitted by a temperature sensor for the temperature control instrument, and then through the temperature control instrument to set the temperature operation, PID control with high-temperature control precision. The conduction oil furnace divides into basis heating and auxiliary heating, and many groups of both basis heating and auxiliary heating to reduce the load of electrical organs. We control each group to prevent the conduction oil ageing when the electrical organs have exorbitant temperature and extend its service life.

- Pressure monitor: A pressure gage is installed both at the hot oil pump and pipe of the heater barrel to show the real-time pressure of the furnace, it will output signal alarm once the pressure below a certain value, meanwhile stop the heat.

- Liquid level monitor: There is a floating controller in the head tank, it can real-time monitor the liquid level, and it will output a signal alarm once the level below a certain value, meanwhile stop the heat.

- Oil in control: Filling pump will open and fill oil into the tank once the oil level below the regular level.

- Main alarm: It is equipped with a sound-light alarm of overtemperature, low pressure, low oil, and function of stopping electricity.

- Main protect: This system has interlocking reaction protection of level, temperature, pressure, etc. It can promptly acousto-optic alarm, and stop heating when anyone place malfunction.

V Main materials configuration

- Mechanical part

- Frame: The material is Q235A, the chassis is 6.3# U-steel, and other are square tubes of 50×50.

- Heating cylinder: Φ219×δ6 seamless steel tube

- Electric heater: Flange stainless steel electric heating pipe

Total power: 250kw

Power: 380VAC 50Hz three-phase and four-wire

Flange heater: HG20592-97 PL200-1.6 RF

Electric heating pipe: the shell is 1Cr18Ni9Ti seamless tube

Heating wire: Cr20Ni80

Insulation resistance: ≥10MΩ

Pressure resistance: 1800V/min

- Terminal box: Wall-hanging, be a part of the furnace

- Insulation: High-quality aluminum silicate cotton, insulation thickness is more than 90mm, the shell is a galvanized sheet of 1.2mm, and its appearance is flat and smooth without any concavo-convex inequality defects.

- Control cabinet: Q235-A, cold plate is δ=2mm, line-in and out at the bottom, color is computer grey.

- Outside plant:

Heater surface: temperature-resistant silver paint

Terminal box: Wall-hanging, be a part of the furnace

Control cabinet: computer grey

- Filter: cast steel

- Valve: cast steel

- Electrical organs

- Temperature controller(PID) : Omron

- Air switch: Chint

- Contactor: Chint

- Indicator light: Chint

- Press-button: Chint

- Switch-button: Chint

- SSR : from Wujie

- Temperature detection: from Shanghai Tianhong

- Overtemperature relay: Chint

- Terminal strip: from Fenghuang

- Pressure gage: from Hillt

VI Scope of supply

- Thermal Oil Heater: 1unit

- Expansion tank: 1unit

- Control cabinet: 1unit

VII Spare parts

Oil pump sealing element: 1 set

VIII Equipment manufacture and acceptance standard

The equipment provided by the supplier should according to the company standard of “Q/320911 RYS2002-2007 Thermal Oil Heater”, and national electrical industry manufacturing standards to manufacture and accept.

IX Environmental requirement

- An indoor space with ventilation or fresh air.

- Ambient temperature is between -10℃ and 45℃.

- No electric conductive dust, and no corrosive gas which can severely damage metal and insulation in the around.

- Without direct sunlight.

- Smooth and strong of the mounting floor without obvious shake.

X Equipment evaluation indexes

- Appearance is free of defects and there is enough rigidity, doesn’t deformation whatever cold state or thermal state

- Sealing parts all use high-temperature metal winding pads, sealed performance is good without leaking.

- The Sealing test, the system does the air-tight test at a pressure of 0.1Mpa.

- The Surface temperature of the furnace is ≦35℃ ( relative to ambient temperature ).

- The Carbon steel surface is painted two antirust paint and two topcoats after rusting removal. And the appearance is smooth, bright and clean, the colour and lustre are consistent.

If need more technical information, please contact us freely.

Leave A Comment