Introduction:

The Electric Heating Tube is electrical components which designed for converting electrical energy into heating energy. It is widely used in various heating area as its simple manufacturing process, low cost, convenient using, convenien installation and no air pollution.

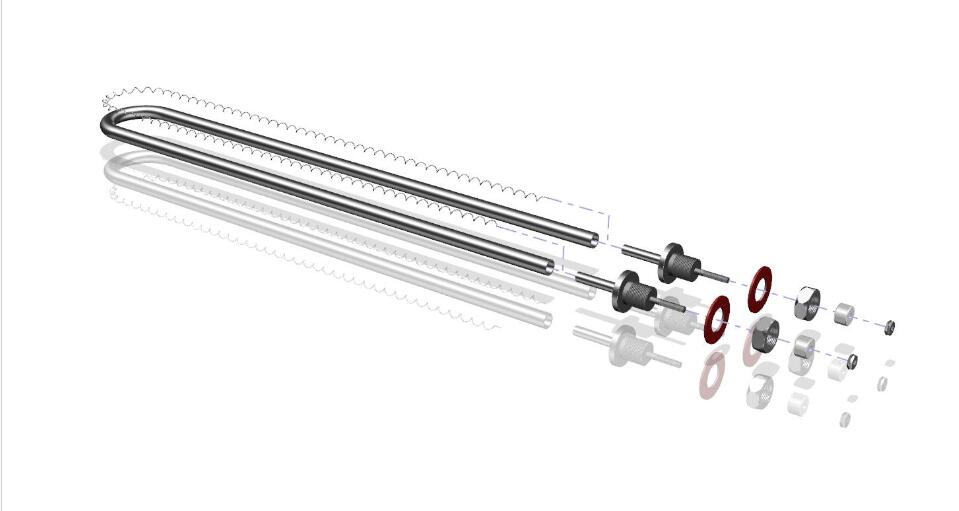

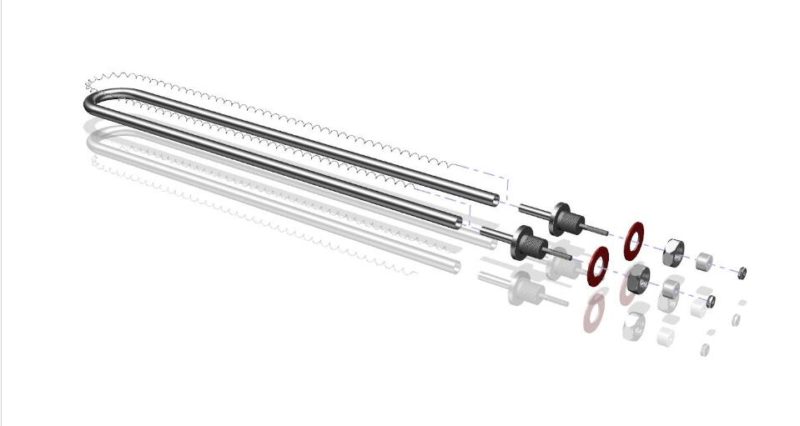

Assembly Drawing

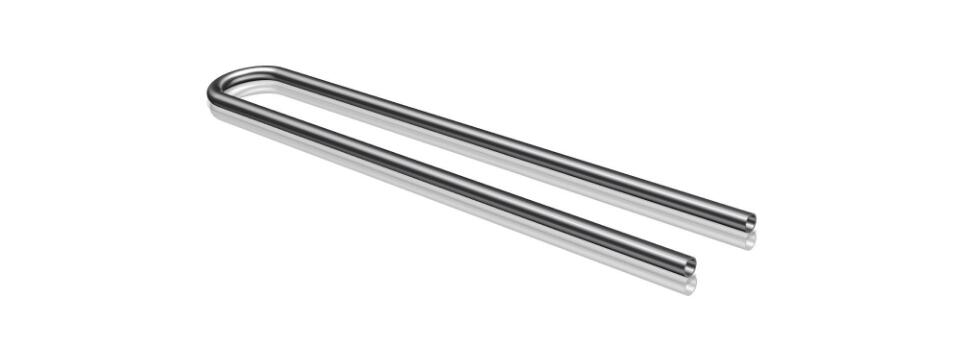

Shell Material

Shell material has Stainless Steel, Carbon Steel, Copper, Titanium, PTFE, Silicon Carbide and other materials. It is the protective layer of the heating tube.

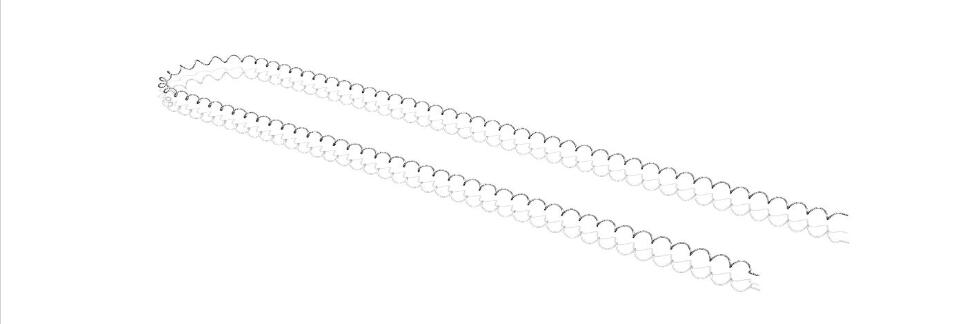

Resistance Wire

Outside the tube, the center line is spirally coiled in the outer tube. The resistance wireis the component which converts the electric energy to the heating energy, so it is the core of heating tubes. The quality affects the life and performance of heating tubes directly. Its material has FeCrAL and Nickel Chromium wire, such as Ni80Cr20, 0Cr25Al5. etc.

Magnesium Oxide

Between the heating tube and heating wire, we need good filler with insulation and thermal performance to transfer heat, and needs same linear expansion coefficient with the heating wire, also need good heat resistance and good shock resistance. It cannot have chemical action with the heating wire and tubes under high temp or room temp.

Magnesium Oxide, Caustic Magnesium, Alumina and clean quartz sand .etc filling material are usually used ( from good to poor performance). If customers donot have special requirements, we all chose good performance of Magnesium Oxide.

The Surface Load

- What is Surface load?

Power per unit area on heating surface.

- The Calculation Formula of surface load:

Surface load(w/cm²)=W/D×π×L(cm)

D=diameter of heating tube; π=3.1415926; L=length of heating part

NOTE: L is length of heating part, not length of tube.Because each heating tube has heating length and cooling length.

- Surface load techncial dates for reference.

| Tube Diameter(mm) | Suface load(w/cm²) |

|---|---|

| Φ6 – Φ10 | ≤22 |

| Φ10.1-Φ14 | ≤20 |

| Φ14.1-Φ18 | ≤16 |

| Φ18.1-Φ22 | ≤12 |

| Φ22.01-Φ40 | ≤10 |

The above surface load refers generally to the metal mold heating. Water heating will be multiplied by 2 to 2.5. Air heating will be 50% to 60%.

Main parameters of electric heating elements.

- Electric voltage: V

- Electric power: W

- Electric frequence: Hz

- Working temperature: ℃

- Tube diameter: mm

- Spreading length: mm

- Weigth: KG

How to develop more advanced electric heating elements is key problems for many enterprises now. Most electric heating elements are made of alloy electric resistance wires as the heating part. The electric heating elements made by us are using the best alloy resistance wires (Ni80Cr20) as the heating part.

If any questions or inquires, please contact us without hestiation.

great article! very straightforward and comprehensibly written.

they also have tiny heaters 12v 30 watts.

a caring company that doesnt shy away from more complicated customization.

recommended!

Good and informative article about electric heaters.

Very good