I Overview

GYZ series vacuum calciner is suitable for cleaning the polymer materials filters and strainers, making them be reused after calcination, and saving the production cost. It is also a kind of environmental protection equipment.

The vacuum calciner applied the characteristics that polymer can be melted at a certain temperature, decomposed under the condiction of high temperature around 300℃ and isolating from air, and complete oxidation when above 400℃ and a little oxygen and certain vacuum degree. Using this characteristics, we first heat the cleaned pieces to the melting temperature, meiting the high polymer on the surface of filters and let them flow down into the waste collecting tank. At this time, surface of the filters remians only a little high polymer and ash content, when the furnace temperature rose up to the cracking temperature ( can according to technological requirements ), open the vacuum pump, lead to a small amount of air to the rest of high polymers, they will be completely oxidation and can get carbon dioxide and water, through the suction of water-ring vacuum pump, the carbon dioxide and water vapour generated in furnace are washed by the spray washer, and then discharged out the furnace. No exhaust gases, smog and ash throughout the working process, just a small number of carbon dioxide, and no more burning is needsd for the exhaust, the water takes away only a small amount of ash.

GYZ series vacuum calciner uses stainless steel electric heating tubes for direct heating, seals are all heat-resistant seal rings, and water protection is not required. So the device has high thermal efficiency, small heating power, temperature rises rapidly, better temperature uniformity, and heater maintenance is convenience, save power and water.

II Cleaning process

Users determine the cleaning process according to the workpiece properties and high polymer’s melting temperature and other conditions, prepared to run the program.

- 1. OA part Use 45min to heat the workpieces to 300℃.

- 2. AB part Furnace temperature insulated at 300℃for 60 minutes, and flow the over 80% polymer melt into the waste holding tank. Increase or decrease this amount of time depend on the polymer content.

- 3. BC part After the AB part, open the vacuum pump, and heat the furnace up to 450℃.

- 4. CD part Furnace temperature insulated at 450℃for 420 minutes, let the remained polymercompletely oxidation and decomposed at the condition of vacuum, high temperature and low oxygen. This is the main stage of cleaning. In this time, the chemical reaction of high polymer in furnace is that: CmHN+O2→CO2↑+H2O↑. Through the suction of water-ring vacuum pump, the carbon dioxide and water vapour generated in furnace are washed by the spray washer, and then discharged out the furnace together with water. As long as the CD part has enough time, never by cleaning pieces stained with organic matter.

- 5. CD part runs end asthe programs are all over, immediatly shut down water and power of the vacuum calciner, only instrument electricity, into the natural cooling state without manual operation.

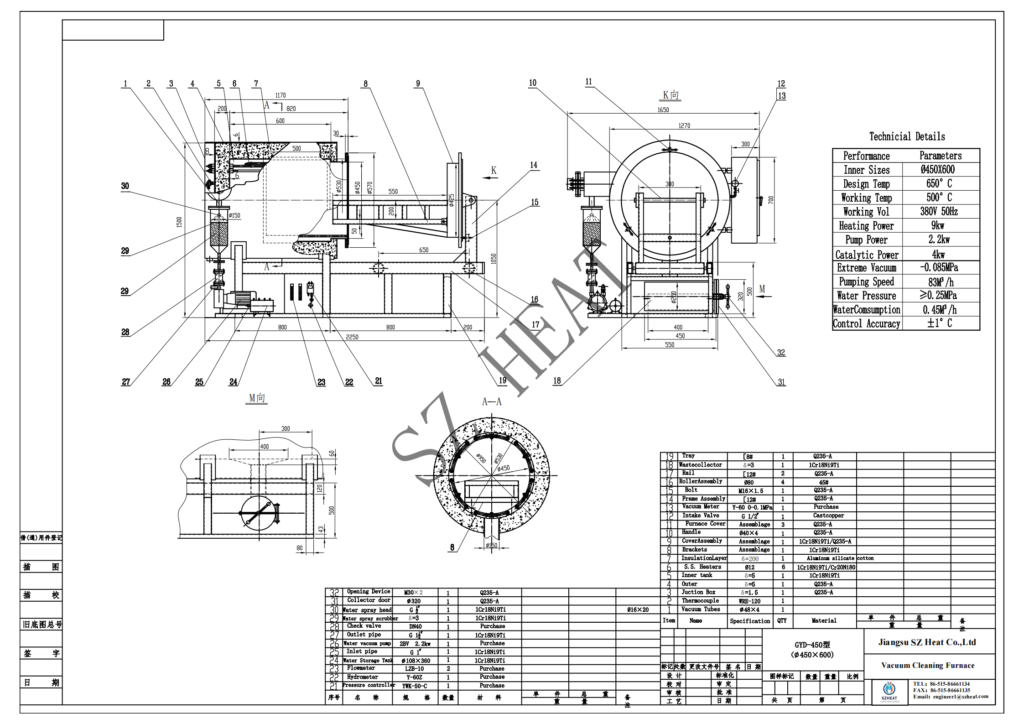

I Unit type: GYZW-700

II Equipment characteristics

Horizontal cylindrical furnace, trolley type structure, stage vehicles directly integrated with the door. This equipment is an independent and integrated working system, and equipped with collection device, vacuum system, water system to ensure the normal operation of the service and the temperature control system services for program. Integration of mechanical, electrical, instrument configuration, when the equipment takes its place, it can proper functioning only users surpport water, electricity and drainage tubes.

III Structural form

- 1. Vacuum hearth

Vacuum hearth is horizontal cylindrical, and consists of furnace cover and working chamber of putting cleaned pieces. The waste collecting tank is at the bottom of the hearth. In order to ensure the melting high polymer smoothly flow into waste collecting tank, there is a funnel-shaped pallet at the bottom of furnace, and located right above the waste collecting tank. Exhaust gas outlet ( vacuum inlet ), air for oxidation inlet and heater installation hole are all in the hearth. High-quality aluminosilicate fibers is filled between the hearth and outer barrel to heat insulation.

The hearth material is SUS304 stainless steel, and furnace outer barrel is high-quality Q235A structural steel.

- 2. Stainless steel electrical heater

The vacuum calciner heater is made up of six “U” type stainless steel electric heat pipe. Heaters are installed in the surrounding of the hearth, the line stretches out the furnace passing through the insulating layer from heater install port, and a junction box in the outside of furnace.

- 3. Waste collecting tank

Waste collecting tank is horizontal, inside is a semi-circle drawer to put the waste,and it is easy to pour out the waste when you pull out the drawer.

- 4. Spray washer

The ash content produced in the anti-blocking device is cleaned by the spray washer and then flow into the water-ring vacuum pump. The spray washer consists of stainless steel barrel and water spray header, stainless steel pall ring for filtration is setted in the barrel, and spray water is the inlet water of the water-ring vacuum pump. The water supply of spray washer is made up of solenoid valve and flowmeter.

- 5. Seal

The furnace cover and door is sealed by double seal-rings, and sealing material is the heat-resistant flexible graphite packing. Waste collecting tank is sealed by heat-resistant silicon rubber.

IV Performance index

- 1. Inner dimensions: φ450×600 ( Dia. × L mm );

- 2. Contour dimension:2250×1650×1500 ( L × W× H mm );

- 3. Working power: 380V/50Hz three phase and four wire;

- 4. Heating power:9kw;

- Catalytic Power: 4KW;

- 6. Vacuum pump power: 2kw;

- 7. Water in: G1″, above PN0.25Mpa is tap water;

- 8. Water out: G1 “, ordinary pressure, water temperature is 40 ~ 50℃;

- 9. Design temperature: 600℃;

- 10. Working temperature: 500℃( adjustable);

- 11. Temperature control precision: ±1℃;

- 12. Control system function

Using Japan Fuji PXR9 temperature controller for automatic temperature control, major loop is solid-state relay contact switch. It has advantages of :

⑴ High degree of automation: users can set the proportional relations between temperature and time according to the cleaning requirement, the pump open and close time, and at the end of cleaning equipment will automatically shut;

⑵ High precision of temperature control: the instrument has function of PID which can make the temperature precision at ±1℃;

⑶ Control loop has complete security warning protection function:

- a. Water-break alarm and automatic cut off the heating power;

- b. Overtemperature alarm and automatic cut off the heating power;

- c. Thermocouple break alarm and automatic cut off the heating

V Equipment material and main components configuration

- 1. Mechanical part

Inner container: heat-resistance stainless steel SUS304, δ=6mm;

Outer barrel: Q235A, δ=6mm;

Thermal insulation: high-quality alumina silicate fibre, δ≥250mm;

Waste collection tank: SUS304, δ=3mm;

Water spray washing device: SUS304, δ=3mm;

Water storage tank: SUS304, δ=3mm;

Heater: stainless steel electrical heated tube, 380V, 18kw in total;

Protect casing: 1Cr18Ni9Ti φ27 x 3.5;

Heating wire: Cr20Ni80;

Vacuum pump: 2BV series, 4kw;

Seal ring: flexible graphite packing, specification is 12 x 12;

Control cabinet: Q235A, δ=2mm, spray plastic;

- 2. Electrical components

Temperature controller: PXR9—TC type, from Japan Fuji;

Temperature detection: WRNE-101, K index, from Shanghai instrument automation factory;

Solid-state relay: JGX-40100ZF (technical grade ), from Wuxi solid-state relay factory;

Air switch: from Chint;

Contactor: from Chint;

Major switch: from Chint;

Overtemperature relay: from Chint;

Indicator light: from Chint;

Press-button: from Chint;

Terminal strip: from Feng huang;

Other electrical components are all domestic famous brand.

VI Scope of supply

Vacuum Cleaning Furnace 1 set

VII Manufacture and acceptance standard

The equipment provided by the supplier should according to the State relevant heating furnace manufacture standards, national electrical industry manufacture standards to manufacture and acceptance.

VIII Equipment evaluation index

- Appearance is free of defects and there is enough rigidity, doesn’t deformation whatever cold state or thermal state;

- Furnace cover convenient operation, flexible, there is no abnormal condition;

- Vacuum pump runs smoothly, the noise is less than 65dB;

- Sealing test, vacuum system does the air-tight test at negative pressure of —0.1Mpa, and water system does the hydrostatic test at pressure of 0.1Mpa;

- Surface temperature of furnace, ≦32℃( relative to ambient temperature );

- Parts and pipelines between the furnace and vacuum pump are connected with flange, easy dismounting;

- Stainless steel polished surface, pickling and passivation treatment. Carbon steel surface is painted two antirust paint and two topcoat after rusting removal. And the appearance is smooth,bright and clean, the colour and lustre is consistent;

- At the end of installation, the equipment is operating without trouble for 72 hours,and meet the following conditions;

- a. Temperature control precision is ±1℃;

- b. Vacuum degree is —0.085Mpa;

- c. Guarantee the workpiece reaches cleaning requirements after washing;

IX Replacement part

- 1. Electrical heating pipe: 2 branches;

- 2. Sealing ring: 12 x12 flexible graphite packing1 set.

Leave A Comment