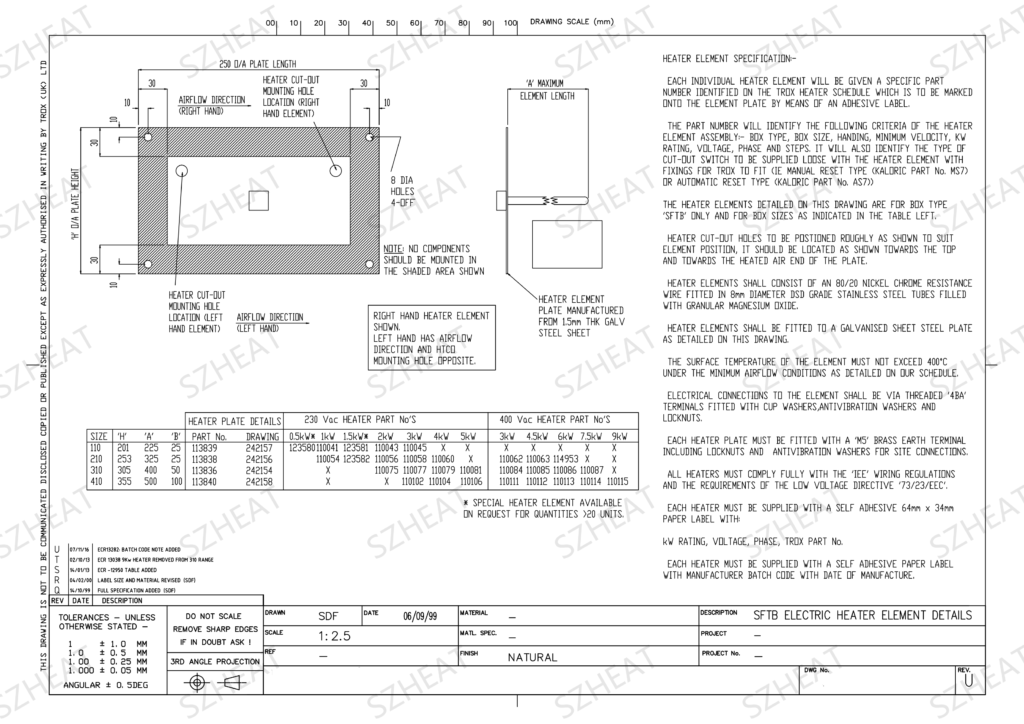

HEATER ELEMENT SPECIFICATION:-

EACH INDIVIDUAL HEATER ELEMENT WILL BE GIVEN A SPECIFIC PART

NUMBER IDENTIFIED ON THE TRDX HEATER SCHEDULE WHICH IS TD BE MARKED DNTD THE ELEMENT PLATE BY MEANS DF AN ADHESIVE LABEL.

THE PART NUMBER WILL IDENTIFY THE FOLLOWING CRITERIA OF THE HEATER ELEMENT ASSEMBLY:- BOX TYPE,BOX SIZE,HANDING,MINIMUM VELOCITY,KW RATING, VOLTAGE, PHASE AND STEPS. IT WILL ALSD IDENTIFY THE TYPE OF CUT-OUT SWITCH T0 BE SUPPLIED LOOSE WITH THE HEATER ELEMENT WITH FIXINGS FOR TROX TO FIT(IE MANUAL RESET TYPE KALORIC PART No, MS7 OR AUTOMATIC RESET TYPE (KALDRIC PART No. AS7))

THE HEATER ELEMENTS DETAILED ON THIS DRAWING ARE FOR BOX TYPE ‘SFTB’ ONLY AND FOR BOX SIZES AS INDICATED IN THE TABLE LEFT.

HEATER CUT-OUT HOLES TO BE POSTIONED ROUGHLY AS SHOWN TO SUIT ELEMENT POSITION, IT SHOULD BE LOCATED AS SHOWN TDWARDS THE TOP AND TOWARDS THF HEATED AIR END OF THF PLATE.

HEATER ELEMENTS SHALL CONSIST OF AN 80/20 NICKEL CHRDME RESISTANCE WIRE FITTED IN 8mm DIAMETER DSD GRADE STAINLESS STEEL TUBES FILLED WITH GRANULAR MAGNESIUM OXIDE.

HEATER ELEMENTS SHALL BE FITTED TO A GALVANISED SHEET STEEL PLATE AS DETAILED ON THIS DRAWING.

THE SURFACE TEMPERATURE OF THE ELEMENT MUST NOT EXCEED 400℃ UNDER THE MINIMUM AIR FLOW CDNDITIONS AS DETAILED ON OUR SCHEDULE.

Leave A Comment